Our collaboration is a statement against the knitting industry’s opaque supply chains, harmful magic potions and linear material blends that enable brands to cut corners and save costs in order to manufacture softness and cheat their way into durability.

UNBORN and KNITWEAR LAB share their ambition to fix the design flaw of the textile industry by reshaping the way garments are designed and believe you have the right to know where our products come from, what the impact is and what the ingredients are for making our garments.

Merino Wool From The Congi Station

Healthy Merino Wool Fibres

The wool fibers that are at the core of our knitwear come from the Congi station in Walcha, NSW, Australia. Now in their fourth generation, the Field family produces exceptionally high-quality wool using modern technology and sustainable, certified herd management processes. The use of non-toxic spray guarantees animal health and safeguards the environment.

Responsible Wool Standard (RWS)

At the Congi Station they understand that fiber quality is a result from the way sheep and land is managed. That is why they have adopted the RWS standard so their flock can enjoy the five freedoms which guarantee the welfare of sheep and the land they graze on.

Wool Combing in Romagnano Sesia, Italy

The opening of bales before being loaded into the openers for transport to the pre loading zones of washing

In the winter the pre loading zones get heated as to soften the wool for better processing during washing.

After washing, carding and multiple combing stages the wool is processed into tops for dyeing or spinning.

Dying & Spinning facility, Valle Mosso, Italy

The wool tops of the Arkaba are dyed with cradle to cradle dyestuff in kettles that can hold up to 6kg of wool.

After washing the wool is dried in temperature chambres before it is spun into yarn at the same facility. Only our Slowool yarn is transported to Tarcento where it is processed at the Cascami Seta Facility.

KNITWEAR LAB

Cradle to Cradle Certified™ 2/30 Nm Arakba yarns. Made from superfine, long staple Merino fibre

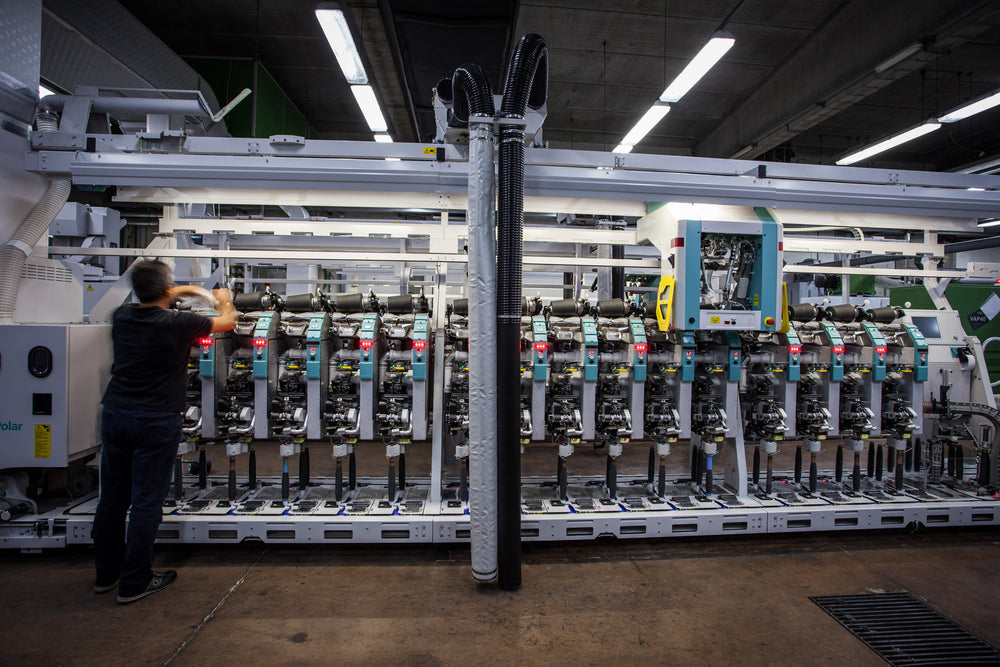

Stoll ADF 16 BW flat-bed knitting machine to create the complex 3D shape of the balaclava

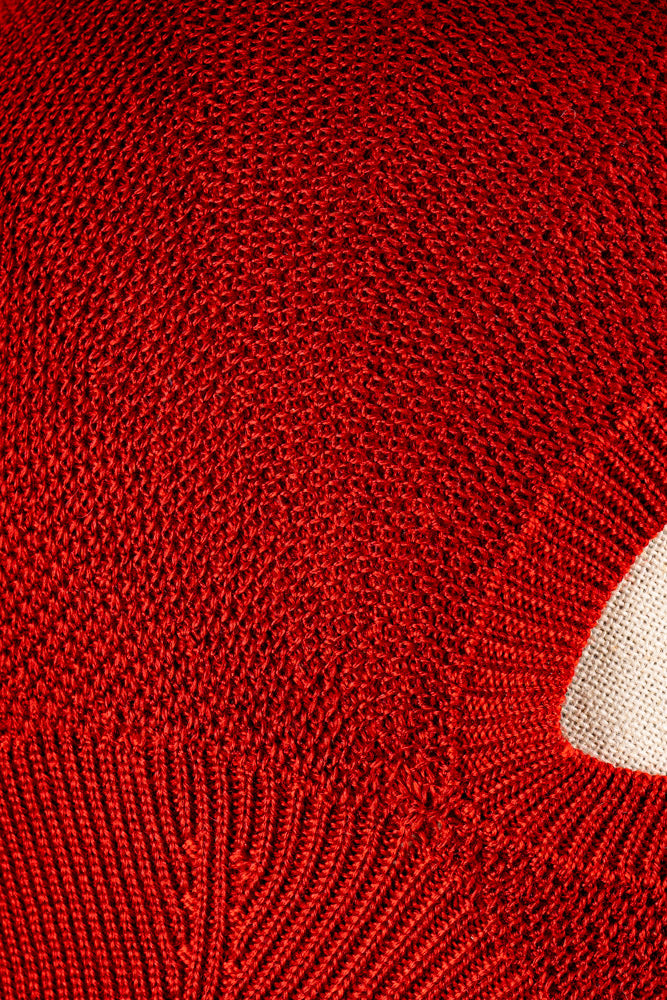

two threads in different shades of Merino wool are used to creates a nice contrast.

The stoll Machine park at the Knitwearlab ranging between 3 Gauge for coarse knits and 18 gaugs for the extra fine knit. The balaclava is knit on a 14 gauge.

The talent behind the balaclava. Modern day knitting requires mathematical insight, machine handling skills, creativity and a design-driven mentality.

The top part is a combination of tuck and jacquard stitch giving this piece its technical look on the outside and a clean sophisticated look on the inside.

The lower half is made from a rib knit for a snug fit around the neck.

Half cardigan for a clean drape on the shoulders eliminating any need for a scarf.